How does Monobloq work?

Insert the 8mm steel rope into the open Monobloq device for 8mm steel ropes (or the 10mm steel rope into the open Monobloq device for 10mm steel ropes).

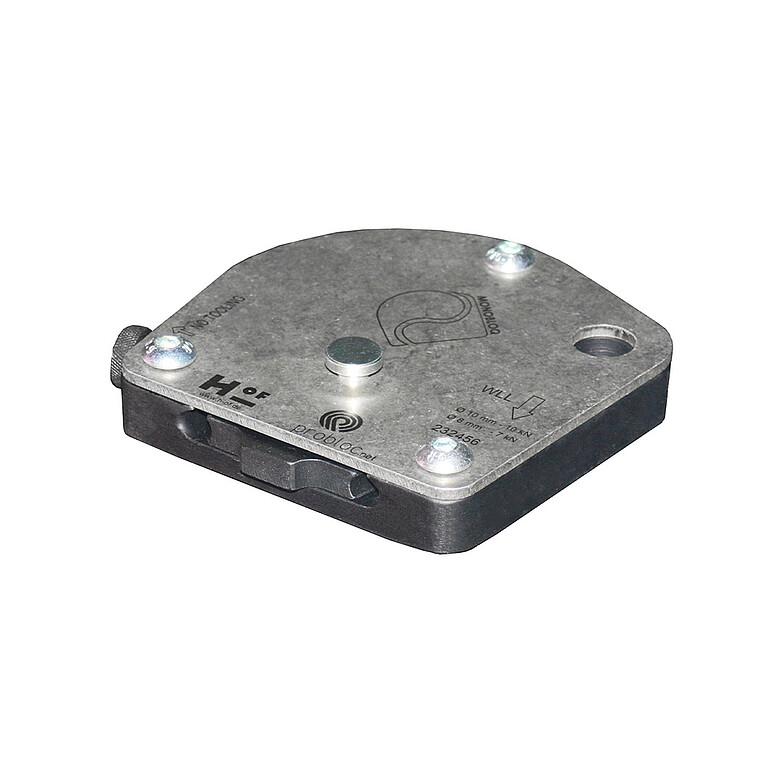

Once the steel rope is in the device, the pressure wedge is placed in the Monobloq body recess and the cover is fixed by 3 fixing screws.

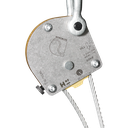

Then the shackle is mounted and gets attached to the structural element.

Once Monobloq is suspended from the shackle, the length of the cable can be adjusted by exerting two-handed effort in the desired direction of travel. To fix the cable at a given point, a manual load must be exerted.

Finally, insert the set screw on the side opposite the load and screw until it is tightened.

Ready for use!

SAFE:

The system is patented and flexible hanging points can be positioned to fit within seconds.

QUICK ADJUSTMENT:

Once the Monobloq is suspended from the shackle, the length of the rope can be adjusted to the desired running direction by applying force with both hands.

Easy to handle:

All you need is a suspension rope and the Monobloq to create a flexible hanging point. The patented system allows positioning in seconds and the installation of up to 8 bridles per hour.

More advantages:

- Less cable stock needed

- Up to 8 bridles per hour with 2 technicians

We offer two different Monobloq bodies: one for 8mm steel ropes and one for 10 mm steel ropes.

To operate with each of these diameters, the corresponding pressure wedge must be used.

In both cases the installation is done in the same way.